38 thermal transfer labels definition

What is thermal transfer printer? - Definition from WhatIs.com - TechTarget A thermal transfer printer is a non-impact printer that uses heat to register an impression on paper. A thermal transfer printer has a printhead containing many small resistive heating pins that on contact, depending on the type of thermal transfer printer, melt wax-based ink onto ordinary paper or burn dots onto special coated paper. Custom Clothing Labels. Custom Woven Labels for Clothing. Folded labels can be folded in half and have a closed edge as well as a heat-sealed cut edge, which is meant to be sewn into the garment. Flat labels are not folded and have a closed edge along the top and bottom. The ends are meant to be folded as we don’t achieve a skin side finished edge, it’s just sealed to be non-fray.

Blank Labels: Direct Thermal vs Thermal Transfer Rolls [Video] Thermal Transfer. Direct Thermal. Bright white paper that can handle heat or sunlight. Bright white paper with a high sensitivity thermal coating. Resistant to fading and smearing. All-temperature adhesive. Ideal for barcode applications. Cost-effective material for grocers. More durable & longer shelf life.

Thermal transfer labels definition

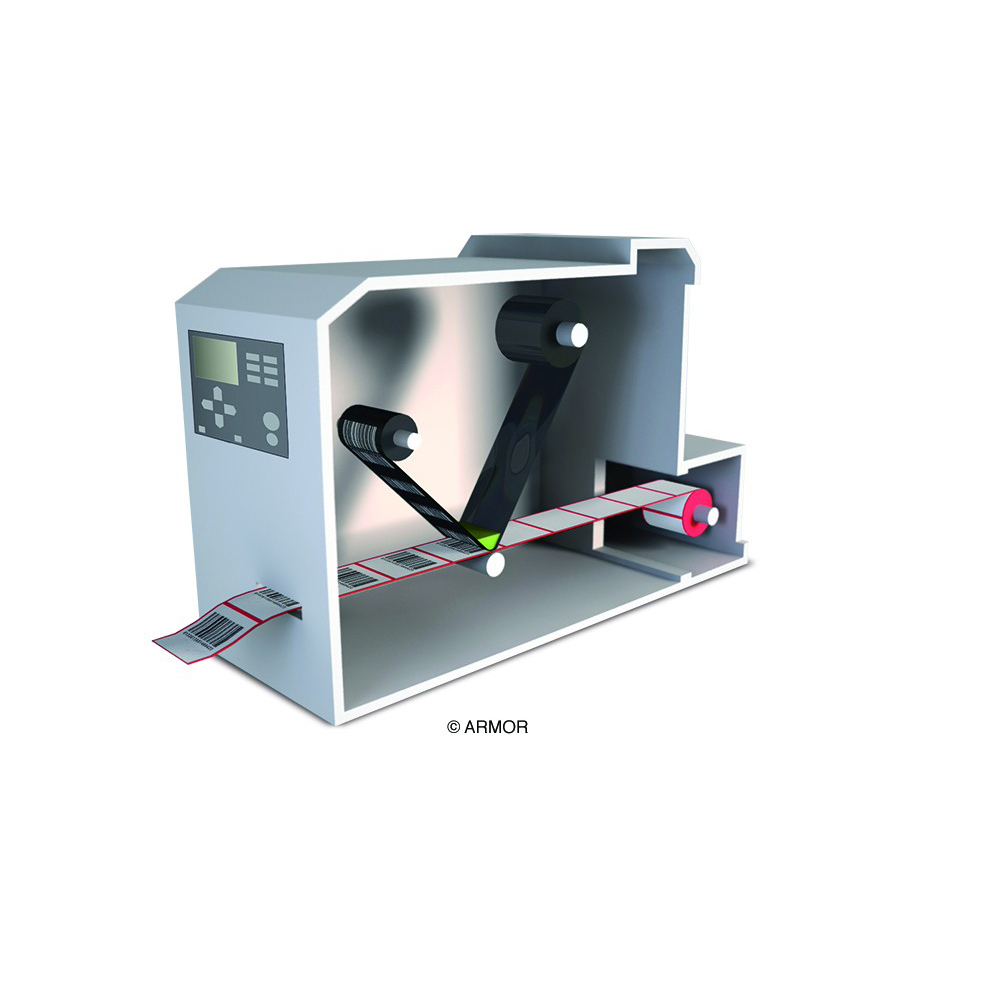

› us › enDirect Thermal and Thermal Transfer Printing | Zebra Thermal Transfer Printing. Thermal transfer printed labels are easily identified by the crisp, often glossy, printed surface. The clarity is achieved by using a thin ribbon roll that when heated by the printhead melts onto the label to form the image. The ink is absorbed so that the image becomes part of the media. Direct Thermal Labels vs. Thermal Transfer Labels - zolemba.com Thermal transfer labels are printed with an ink ribbon within a thermal transfer label printer. These labels do not have a special layer because they are printed with ink instead. The ink ribbon is heated in the printer so that the necessary printing is placed on the labels. What does "Thermal Transfer" mean on Product Labels? Conversely, "Thermal Transfer" printers use special ribbons with colored ink that gets melted by the printhead in the chosen areas and the ink "transferred" to the material being printed on (hence the name). This technology is often used by customers wishing to "overprint" product labels with variable data (such as expiry dates, lot numbers etc).

Thermal transfer labels definition. Overview of Thermal Transfer Labels When compared with direct thermal, the advantage of thermal transfer label is its significantly longer shelf-life, durability, clearer imprinted image on the label, better scannability, etc. The only "draw-back" is a slightly higher cost of production, because thermal transfer printing process requires a ribbon that melts the ink onto the ... Thermal Label Printing: The Basics - advancedlabelsnw.com The printed labels could then be processed through a Thermal Transfer printer in smaller quantities to meet the client's specific requirements. The purpose for doing so, beyond the need to revise any one of these additions on the fly and provide "just in time" label inventory within the client's operation, is commonly to reduce the inherent ... Direct Thermal vs Thermal Transfer Labels | Diversified Labeling Solutions What Are Thermal Transfer Labels? Thermal transfer labels use ribbons that hold ink to "transfer" the image onto the media. This is done with the same printheads used in direct thermal printing. A lot of the roll media printers are set up to print both T.T. and D.T. The determining factor is whether there is room or a place to hold the ribbon roll. en.wikipedia.org › wiki › ResistanceResistance - Wikipedia Thermal shock resistance, a measure of resistance of a material to temperature jumps. Thermal resistance, a measure of difficulty of heat transfer through a substance Thermal conductivity, how well heat is conducted through a substance; Thermal resistance in electronics, heat considerations in electronics design; Other uses

Home - ThermalTransferLabels.com Thermal Transfer Printer Review - Sato CL4NX Printer The Sato CL4NX printer series of thermal transfer industrial printers are among the best in their class. They are widely used across industries including aerospace, automotive, education,…. Read More ». March 24, 2022. Terminology for Thermal Transfer Products (Barcode Ribbon ... Thermal Transfer Printing. Thermal-transfer printing is a fast and clean digital printing method with no warm-up or cooling time required. During the print process, material is applied to paper or some other medium by melting a coating of ribbon so that it stays glued to the receiving material on which the print is applied. Welcome to CK-12 Foundation | CK-12 Foundation FlexBook Platform®, FlexBook®, FlexLet® and FlexCard™ are registered trademarks of CK-12 Foundation. › wp-content › uploadsTroubleshooting Thermal Transfer Printing Problems Troubleshooting Thermal Transfer Printing Problems Possible Cause Corrective Action Poor Edge Definition (bar codes and alphanumerics) Print speed is too high Reduce print speed; do not rotate symbol Ribbon and media are incompatible Test alternative ribbon or media Bar Codes Smearing (bar code edges "bleeding" or "feathering")

Direct Thermal vs Thermal Transfer Labels - Barcode Blog Thermal Transfer Thermal transfer (TT) printing requires a ribbon to print. The ribbon acts as a buffer between the print head and the label material. As the thermal ribbon passes over the heated print head, it melts onto the label. This printing method produces a darker text for more clear images. Direct Thermal and Thermal Transfer Printing | Zebra Thermal Transfer Printing. Thermal transfer printed labels are easily identified by the crisp, often glossy, printed surface. The clarity is achieved by using a thin ribbon roll that when heated by the printhead melts onto the label to form the image. The ink is absorbed so that the image becomes part of the media. Considerations for Thermal Transfer Labels | Mammoth Labels & Packaging To start, thermal transfer labels have excellent print definition for text, images and barcodes. These types of printers can produce stable and durable images that are long-lasting and resistant to fading. Self Adhesive Labels | Plain & Printed Label Manufacturer Hamilton Adhesive Labels Ltd is proud to be one of the UK's leading independent converters of Multicolour Printed and Plain Self Adhesive Labels. Hamilton manufactures an extensive variety of bespoke label products for numerous industry sectors. Including Food Labels, Beverege Labels, Chemical Labels, Logistics Labels and more.

The Difference Between Thermal Transfer and Direct Thermal Labels Thermal Transfer Printing "Thermal transfer labels are characterised by the crisp printed surface that is often glossy. The printer heats a thin ribbon roll until it melts and forms a clear image. Then, the media absorbs the ink, allowing the image to cling deeply.", explains Direct Appliance Rentals CEO Karina Wolfin.

Thermal Transfer Printing - What is thermal transfer printing? Definition of THERMAL TRANSFER PRINTING: A method of printing; this process creates an image by using a thermal print head to melt specific areas of a ribbon so that these areas are transferred to the substrate being printed.

Thermal Labels | Adhesive labels UK & Northern Ireland | Direct Thermal Labels | Thermal ...

Resistance - Wikipedia Thermal shock resistance, a measure of resistance of a material to temperature jumps. Thermal resistance, a measure of difficulty of heat transfer through a substance Thermal conductivity, how well heat is conducted through a substance; Thermal resistance in electronics, heat considerations in electronics design; Other uses

Instruction Set of a Processor: Definition & Components Jan 24, 2022 · The Instruction Set. The closer we get to the core of a computer, the more unfamiliar things may appear. In fact, we are getting closer and closer to the atoms of the computer: the 1s and 0s!

Direct Thermal V.S. Thermal Transfer - Abbott Label Thermal Transfer. Ideal for high volume use applications. Utilizes thermal transfer ribbon. Color printing—great for logo and product branding labels. Print accuracy, precise edge definition—great for barcode printing. Resistant to fading and smearing. Durable & Versatile. Can print on a variety of label materials.

How to Determine Whether a Label is Thermal Transfer or ... - RighterTrack The only difference between direct thermal material and thermal transfer material is the chemical coating present on direct thermal materials. I like to think of this coating as a while layer of "pixel bubbles" that get broken when heated or when the white barrier is removed. Generally, there is no way to tell just by looking at the label.

Troubleshooting Thermal Transfer Printing Problems Troubleshooting Thermal Transfer Printing Problems Possible Cause Corrective Action Poor Edge Definition (bar codes and alphanumerics) Print speed is too high Reduce print speed; do not rotate symbol Ribbon and media are incompatible Test alternative ribbon or media Bar Codes Smearing (bar code edges "bleeding" or "feathering")

Thermal Transfer Labels (Requires A Thermal Ribbon) Thermal Transfer Labels (White) Laser / Inkjet Labels. Laser / Inkjet Labels (White) Laser / Inkjet Labels (Color) Laser / Inkjet Labels (Clear) Tags. Thermal Transfer Tags (Requires A Thermal Ribbon) Thermal Transfer Tags (White) Ribbons. Thermal Ribbons (Color) Datamax/Honeywell Colored Ribbons;

What is the Difference between Thermal Transfer and Direct Thermal Labels? A label produced with the thermal transfer method will not blacken when a fingernail or other hard object is drawn across it. Thermal transfer labels are used for permanent solutions such as product identification, asset tags, tickets, and certification labels. Their durability also makes them appropriate for cold storage and outdoor applications.

Understanding Thermal Labels: Direct Thermal vs. Thermal Transfer Thermal labels are the perfect solution for printing information on demand such as barcodes, ingredients and dates. There are two methods to consider, each with their own advantages; direct thermal and thermal transfer. Choosing the right thermal option requires matching application requirements with the capabilities of your printer.

Direct Thermal Label vs. Thermal Transfer Label Difference (Infographic ... Thermal transfer labels are used for the thermal transfer printer. The print head applies heat to the ribbon, which melts either wax or a special resin onto the label media, bonding to it. You will be able to see the ink is removed from the ribbon to be bonded with the label to create your image. Quick Tips:

What is Thermal-Transfer? - knowledge.labtag.com What is Thermal-Transfer? Thermal-transfer printing uses a ribbon to print information on labels. The heated print-head is used to melt the ink coating of the ribbon, transferring it to the label. Since the label itself is not reactive, the print produced by this method is much more stable and a lot more durable.

Thermal Transfer vs Direct Thermal - Passion Labels Thermal Transfer: When Thermal Transfer printing, you are using a thermal ribbon, which acts as a buffer between the printhead and label material. Thermal ribbons are designed with an acrylic back-coating, that serves to increase printhead life, by reducing static and friction.

Printing Supplies | Zebra Zebra's portfolio of barcode labels and tags include paper and synthetic materials for thermal transfer or direct thermal printing. Hospital Bracelet and Patient ID Wristbands Zebra's portfolio of hospital bracelets and patient id wristbands include a wide range of the most durable and easy to use direct-print laser and thermal wristbands.

Adhesive Labels | Plain & Printed Label Manufacturer ... If you have at least 2 years’ experience in sales within the packaging industry and are interested in a new role, send your CV in the first instance to marketing@hamilton-labels.co.uk Reply on Twitter 1352177301115588608 Retweet on Twitter 1352177301115588608 Like on Twitter 1352177301115588608 Twitter 1352177301115588608

Post a Comment for "38 thermal transfer labels definition"